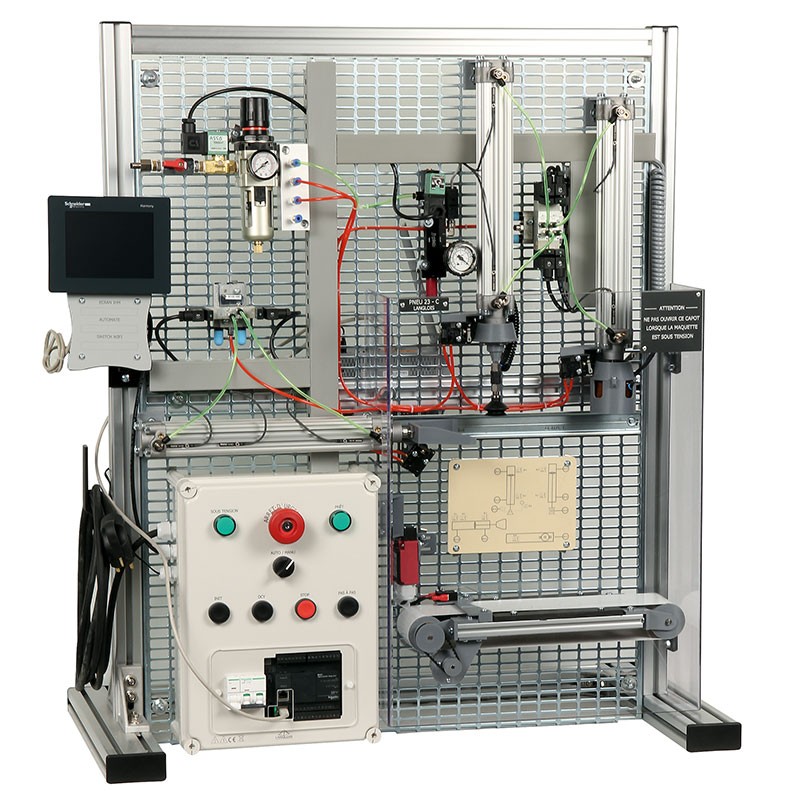

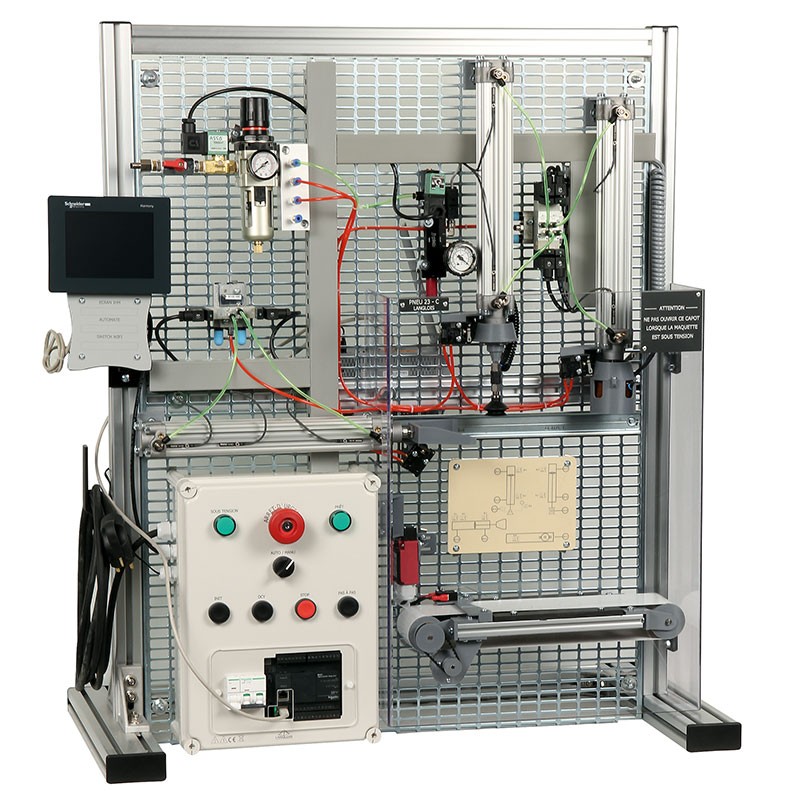

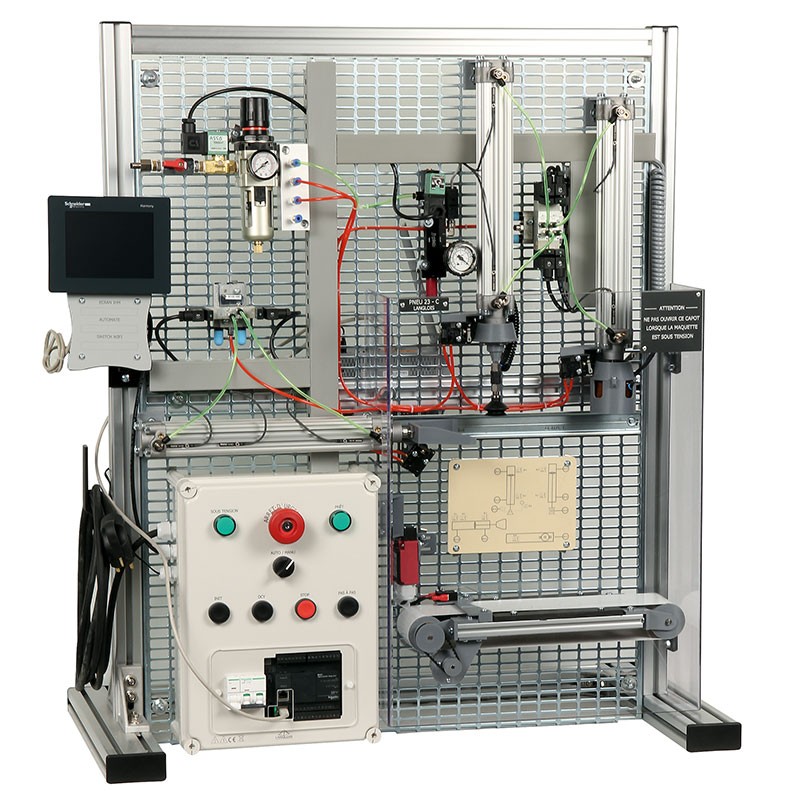

The conveyor belt is either controlled by the automatic system and the end of belt detection switch or by being forced into operation. An electromagnet illustrates picking up by a magnetic field. PNEU** is connected to the air network by splined terminal placed on the valve block of stop + regulator + filter + distribution output by quick coupling.

The model is delivered ready for use (the electric part is completely wired and all the pneumatic connections made). The quick-fit joints allow dismounting/reassembly of pneumatic interconnections with Ø4mm tubes of various colors. A manual gives details of the operation of all the electro-pneumatic components used and their adjustment. Several cycles are described, including one complete with its grafcet.

EDUCATIONAL OBJECTIVES (following versions)

Introduction to pneumatic components

Commissioning, handling of pneumatic equipment

Controlling the system in manual mode

System control in sequential mode

PLC programming approach

System control in automatic mode

Configure and program a PLC

Configure and program an HMI

Become familiar with supervision

Study Ethernet / IP addressing

Study a communication by Wifi

PRACTICAL WORKS (following versions)

Model maintenance

Security verification

Study of the operating cycle

Study and production of the electrical and pneumatic wiring diagram

Realization of GRAFCET, LADDER and Chronogram diagrams

Using the model in manual mode

Use of the model in sequential mode

Use of the model via the automatic order

PLC programming via USB or Ethernet

Using PLC Programming Software

Ethernet Network Setup

Loading, modification, creation of supervision programs

Carry out the Wifi configuration for ordering on a tablet or smartphone

Free

quotation

Answer

under 48H00

Delivery

worldwide

2 years warranty

for all our products

Export service

available

You can't find a product,

You want technical informations,

You want to talk with us

Contact us